Ultracongeladores Telstar serie Igloo

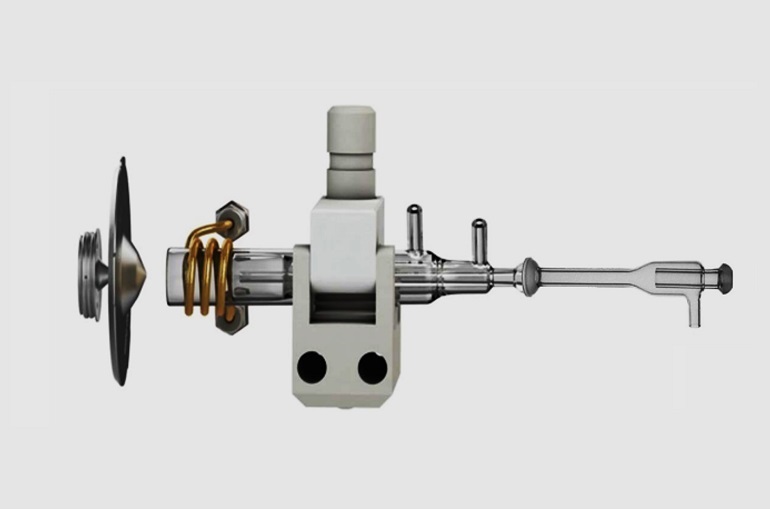

Telstar ha presentado una nueva línea tecnológica de ultracongeladores de baja temperatura (-86ºC y -45ºC). Gracias a su tecnología de aislamiento por panel de vacío y al uso de refrigerantes ecológicos estándar, éste es el ultracongelador más completo y ecológico del mercado. La máxima seguridad de sus valiosas muestras está garantizada gracias a un sistema de refrigeración de gran capacidad. Estos ultracongeladores están disponibles en diferentes capacidades entre 370 y 830 litros.

Aplicaciones

- Almacenamiento de células madre (laboratorios de investigación / banco de células madre)

- Almacenamiento de virus / bacterias (virología / bacteriología)

- Almacenamiento de médula ósea y tejidos (patología / cirugía)

- Componentes sanguíneos / glóbulos rojos (bancos de sangre)

- ADN, líneas celulares, enzimas, proteínas

- Hospitales universitarios

- Industria farmacéutica

- Clínicas de fecundación in vitro

- Centros oncológicos

- Depuradoras

Inycon distribuimos estos congeladores en toda España. cualquier necesidad que usted tenga al respecto , por favor haganosla saber.

Luis de Miguel

Comentarios recientes